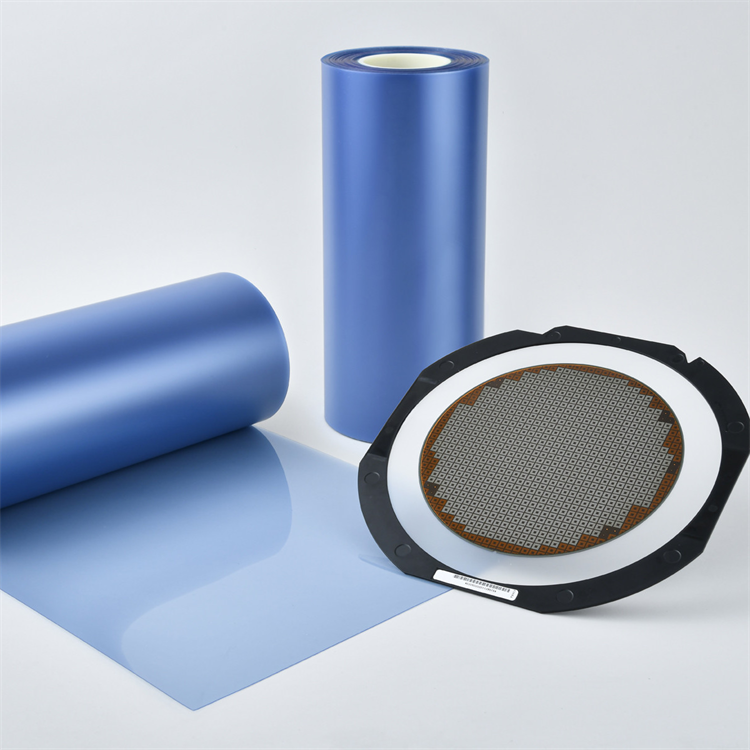

Die Cutting UV Dicing Tape for Wafer Backgrinding

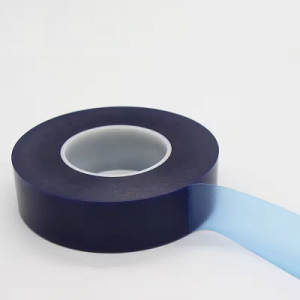

1. Provides strong adhesion during cutting.

2. Rapid response to UV irradiation, improving work efficiency.

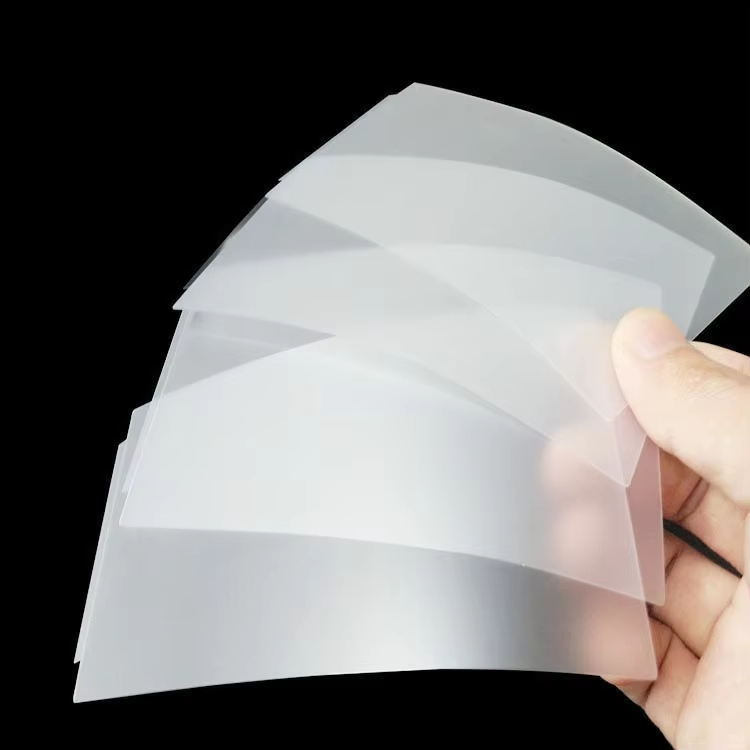

3. Maintains wafer integrity and minimizes chip loss during processing.

4. Ensures firm wafer settlement, preventing movement, falling off, and water permeation.

5. Offers moderate flexibility.

6. Offers UV tapes and customizable sizes to meet individual requirements.

7. Excellent cutting and loading performance.

8. Suitable for low-temperature applications on the backside of the wafer.

| Model | AHS-6309 | AHS-6313 | AHS-6317 | AHS-6306 | AHS-6313-1 |

| Product Name | UV Dicing Tape | UV Dicing Tape | UV Dicing Tape | UV Dicing Tape | UV Dicing Tape |

| TotalThickness (mm) | 0.09 | 0.13 | 0.17 | 0.06 | 0.13 |

| Base Film Thickness(mm) | 0.08 | 0.1 | 0.15 | 0.05 | 0.1 |

| Base Film | PO | PO | PO | PET | PET |

| Liner | PET film | PET-36 | PET-36 | PET-25 | PET-36 |

| Adhesive | Acrylic | Acrylic | Acrylic | Acrylic | Acrylic |

| Peel force (Before UV) | 300gf/25mm | 1000gf/25mm | 1200gf/25mm | 800gf/25mm | 2000gf/25mm |

| Peel force (After UV) | 10gf/25mm | 20gf/25mm | 20gf/25mm | 10gf/25mm | 25gf/25mm |

| Tensile Strength (N/10mm) |

MD:21N/10mm TD:18N/10mm | MD:26kg/mm2 TD:22kg/mm2 | MD:38N/10mm TD:31N/10mm | MD:19kg/mm2 TD:21kg/mm2 | MD:21kg/mm2 TD:23kg/mm2 |

| Elongation(%) | MD:600% TD:600% | MD:600% TD:600% | MD:600% TD:600% | MD:140% TD:120% | MD:150% TD:130% |

| Surface Resistance | / | / | / | 10^9-11 | 10^9-11 |

* Wafer grinding and cutting

* Ceramic components and LED radiator substrate cutting

* Glass substrate polishing and cutting

* Easy remova

* Temporary protection

Write your message here and send it to us