Protective Film

-

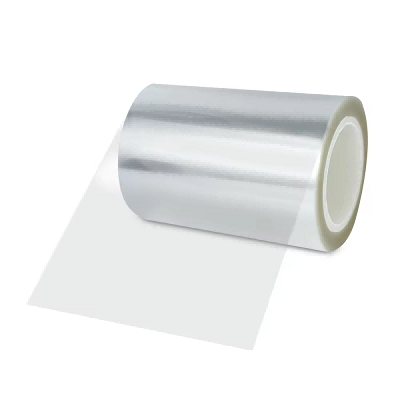

Die Cutting UV Dicing Tape for Wafer Backgrinding

UV Dicing Tape is made with a PO or PET film substrate, coated with acrylic adhesive and combined with a PET release film. It has high transmittance and strong initial tack. The adhesive strength decreases after UV irradiation. This double-sided tape is designed for wafer grinding, cutting, and fine electronic component processing. It is also suitable for cutting small parts. It provides strong adhesion during grinding and cutting, ensuring precise work. After processing, moderate ultraviolet radiation instantly reduces the adhesive strength, allowing easy removal without residue or surface contamination. The IC remains intact during irradiation.

-

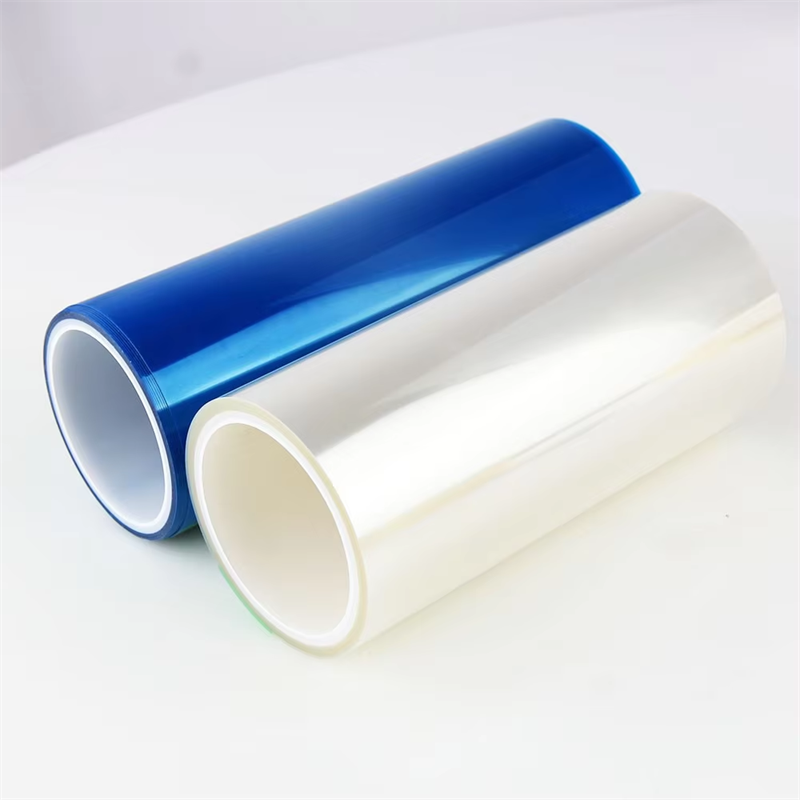

PET Protective Film for Electronic Screen Glass Protection

PET protective film is a thin layer that acts as a shield for objects. It’s created using PET material and a special adhesive that helps it stick firmly. This film offers a smooth surface, great resistance to weather conditions, protection against high temperatures, and clear visibility. Plus, it can be easily removed without leaving any sticky residue behind. People often use PET protective film on electronic devices like mobile phone screens, LED displays, and digital cameras. Its purpose is to guard against scratches caused by external elements and maintain the product’s appearance.

-

Tesa 50530 Alternative Car Transport Wrap for Freshly Painted Car Bodies

Car Transport Wrap is a temporary adhesive-backed film applied to protect freshly painted car bodies. Due to the good UV-resistance and perfect paint compatibility, this film shields the car’s paintwork from scratches, chips, dirt, and other potential damage. It is typically applied to vulnerable areas such as the front bumper, hood, and side mirrors. The film is easy to apply and remove, leaving no residue, ensuring the vehicle arrives in pristine condition. Also, it is an ideal choice to replace tesa 50530, 50560 and 50535.

-

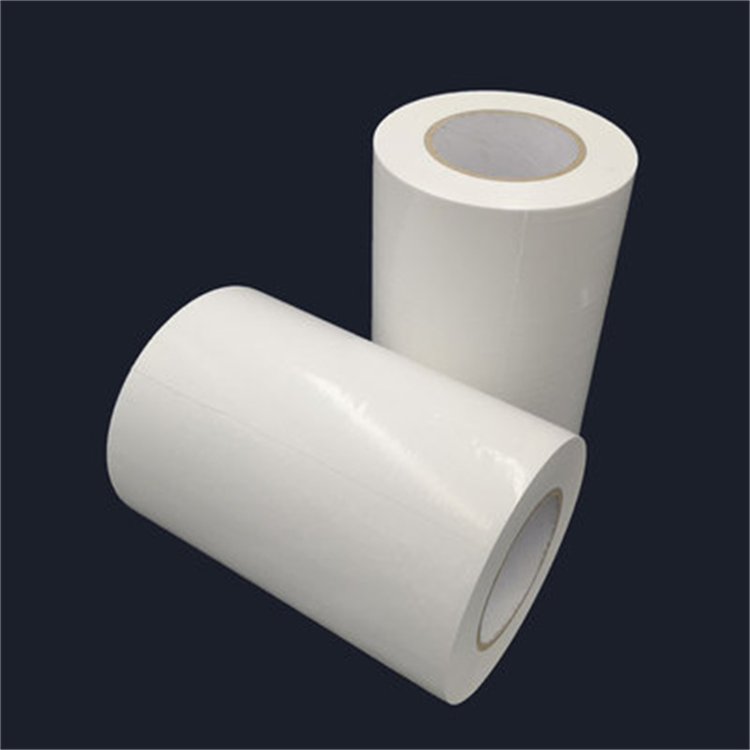

PE Protective Film Clear Polyethylene Film

PE (Polyethylene) protective film is a common protective material used to shield various surfaces during manufacturing, transportation, storage, and installation. It prevents damage, dirt, and other contaminants from affecting the surface. The film is made from polyethylene, offering good flexibility and toughness. It can be transparent, semi-transparent, or opaque depending on specific requirements. PE protective film is easy to apply and remove, leaving no residue, making it ideal for protecting surfaces like glass, metal, plastic, and painted materials.

-

PU Protective Film Polyurethane Film

PU (Polyurethane) protective film is a versatile protective material known for its durability and elasticity. It is commonly used to safeguard surfaces from scratches, impacts, and abrasions. Made from polyurethane, this film provides excellent clarity and can conform to complex shapes, making it ideal for applications that require both protection and aesthetics. PU protective film is often used on electronic screens, automotive surfaces, and furniture. It offers high resistance to chemicals and UV light, ensuring long-lasting protection. Additionally, it is easy to apply and remove, typically without leaving any residue behind.